Atnet™ is a modular, stand alone, easily integrable functional testing system for electronics products

Functional testing

Quality assurance testing is a requirement at any scale, and functional testing guarantees that a product performs as designed, without production defects. Optical inspection and flying probe testing are a good first line of defense, but only functional testing can achieve the test-coverage required for highest quality assurance.

Furthermore, functional testing provides the best opportunity within the production process to program, configure, and calibrate the product.

With a high degree of automation, fast and reliable functional tests can be implemented with minimal operator input.

For who?

OEM’s and product owners

Take control of your quality assurance and critical firmware interaction steps. Have full traceability of produced assemblies and printed circuit board. Log data for Industry 4.0 analysis, or product passports.

EMS’s and assembly services

Enhance the width and quality of your offered services, and provide high quality assurance. Reduce RMA’s and repair-efforts by catching issues and defects early. Have full logs of production times and yield statistics.

Current situation

Large organizations have dedicated engineering teams specialized in production and quality assurance: “Test engineering”, “NPI’, or “Industrialization engineering”

Smaller product owners usually lack the resources and knowhow to specialize in this field. Simultaneously, many EMS’s and assembly houses do not provide this service due to a similar lack of knowhow and engineering resources outside of their core business.

This frequently leads to design engineers being tasked with the manufacture of such a system, leading to one-off, poorly optimized, poorly maintainable, and highly customized solutions. These can cause excessive test time and lowered yield, which induces unforeseen costs for both manufacturer and product owners.

ATNET system

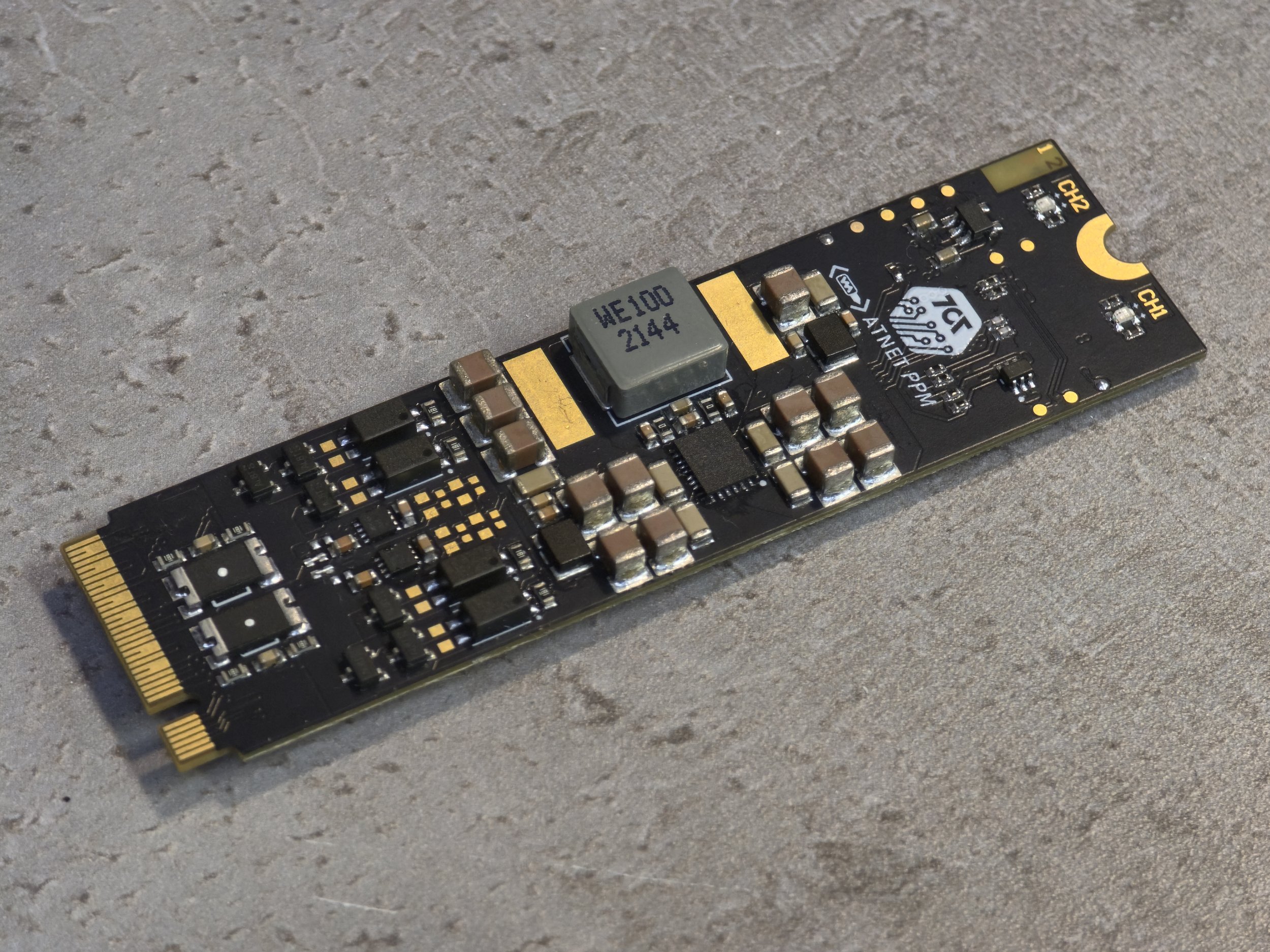

7c7 Engineering aims to resolve these issues by introducing the ATNET testing ecosystem - A modular approach to functional testing, for both PCB tests and final testing of fully assembled products.

Our expertise in industrialization engineering allows us to support the creation of a test-setup from definition of the required behavior, up to start-up in production. Using our in-house developed modules and ATNET architecture, we can integrate a multitude of tests for a wide array of requirements.

A service beyond the hardware

The ATNET hardware is abstracted through a robust client-server websocket API. But we offer more than just the hardware - through Testing as a Service, we provide a full solution for your testing needs, including the hosting of your data in our cloud solution with user portal, and a service level agreement for setup maintenance and debugging.

ATNET features

-

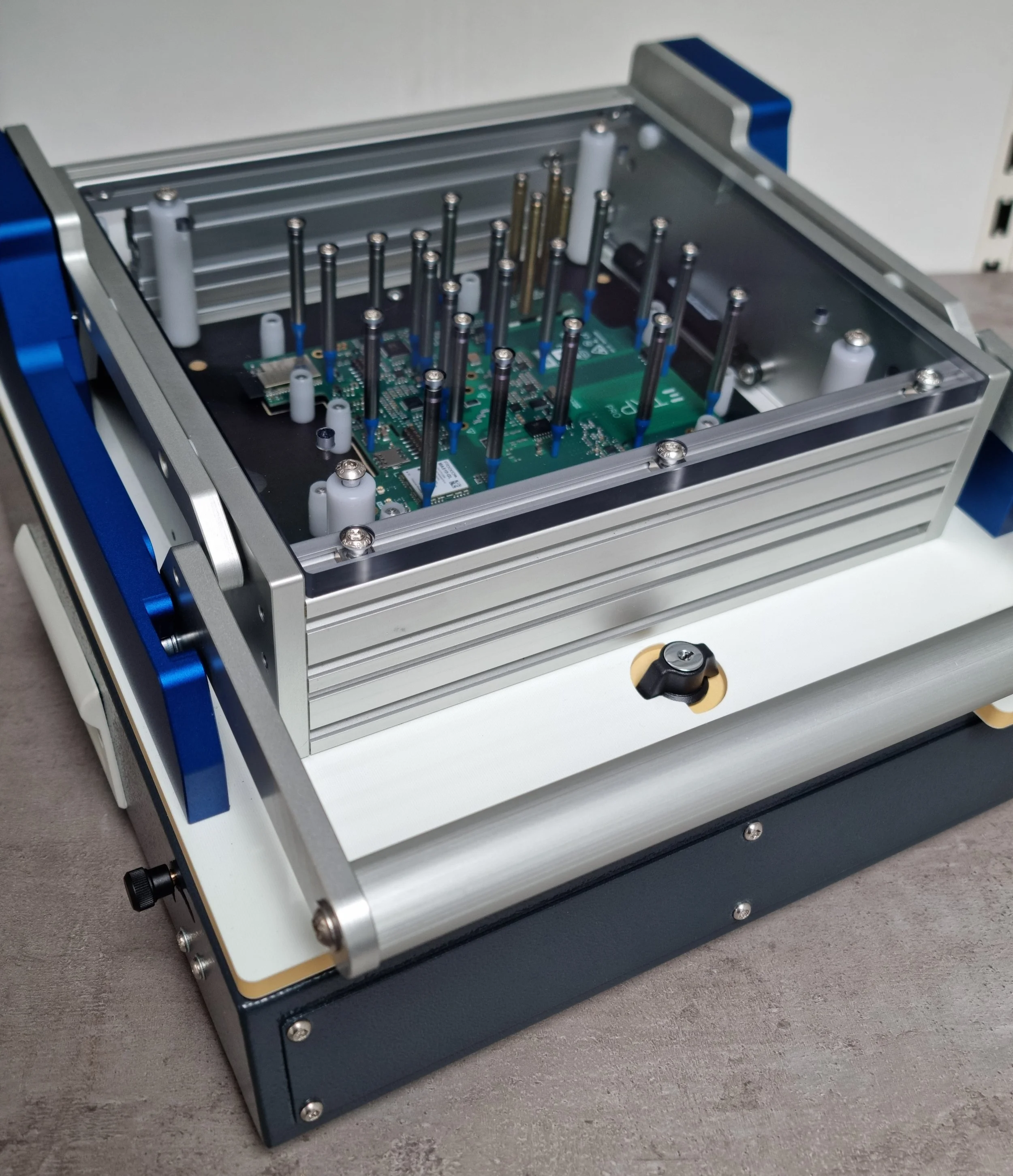

Stand-alone

The ATNET testsystem is designed to be compact, self-contained, and movable. This contrasts with some test-tower based systems, which can cause lock-in with the ecosystem and particular installation location.

External equipment dependencies are limited to a minimum, and all testing is done through a centralized built-in controller.

This allows the system to be fully documented, reproducible, and duplicable for production scale-up scenario’s

-

Modular

A modular approach was used in the development of the testing solutions for different functional testing requirements. This allows standard building blocks to be used for recurring tasks, such as analog measurements, digital IO, communications interfaces, and more.

A modular system allows easy swapping for maintenance and calibration, improving test up-time and maintainability. -

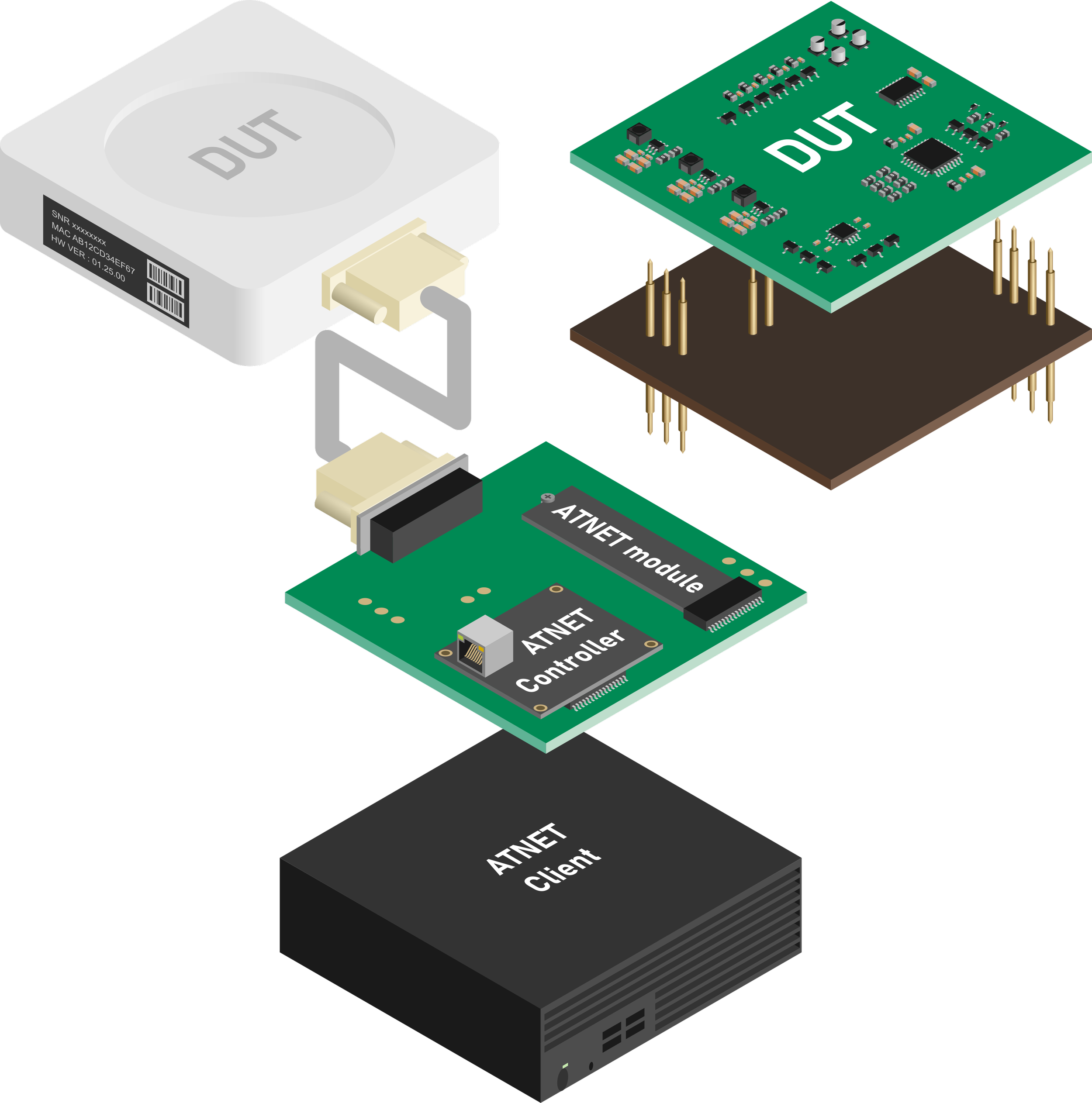

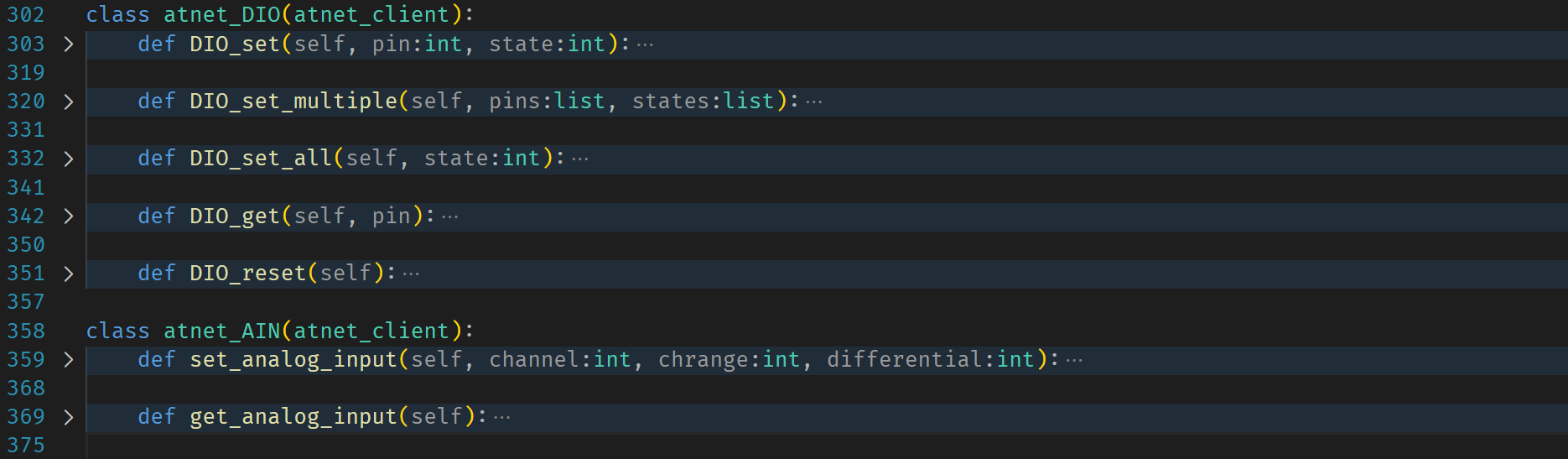

Robust websocket API

The physical testsystem is abstracted from the testing sequence cotroller and data collection through a client-server architecture, with a robust websocket-based API.

Our Python implementation of the ATNET API has a proven track record of fast and effective integration into the NI TestStand sequencer

-

Confined customization

The ATNET architecture is such that the customization for different client requirements is limited to a simple interconnect PCB. For PCB testsystems, an additional custom needle-bed will be manufactured to fit existing jig housings.

This approach allows to keep costs low, while enable fast engineering turnaround times. From test requirement definition, to final integration and approval.